The work on these seat backs seems simple compared to some recent activities, but nevertheless takes time to do right.

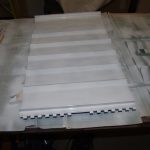

Typically I cut the parts, debur and scotchbrite, then layout before further processing.

Typically I cut the parts, debur and scotchbrite, then layout before further processing.

Fastening holes are measured on the rear seat back corrugated material, then #30 match drilled with angle brackets.

Fastening holes are measured on the rear seat back corrugated material, then #30 match drilled with angle brackets.

Upper and lower angles are measured and #30 holes fabricated with the drill press. These become the template for holes in the corrugated material.

Upper and lower angles are measured and #30 holes fabricated with the drill press. These become the template for holes in the corrugated material.

The upper angles needed to be rounded on the inside for a tight, nesting fit with the rear seat back. The bench sander and scotchbrite wheel were used to provide the relief. After dimpling and countersinking as specified the areas joined together are self-etch primed.

The upper angles needed to be rounded on the inside for a tight, nesting fit with the rear seat back. The bench sander and scotchbrite wheel were used to provide the relief. After dimpling and countersinking as specified the areas joined together are self-etch primed.

The alligator-jaw pneumatic squeezer is used to rivet the parts together.

The alligator-jaw pneumatic squeezer is used to rivet the parts together.

The almost finished seat backs are test fit for lower hinge alignment, then riveted together. Last step is a light coat of sandable primer. Eventually they will be painted the same Boeing 707 grey as the rest of the interior.

The almost finished seat backs are test fit for lower hinge alignment, then riveted together. Last step is a light coat of sandable primer. Eventually they will be painted the same Boeing 707 grey as the rest of the interior.