The tedious work of sanding, fitting, aligning, and build-up continue on the fiberglass tips for the elevator and horizontal stabilizer. The nice part about fiberglass is you can add or subtract material as desired. The down side is having to wait at least 24 hours between operations.

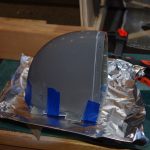

Here is a case of trying to level the HS tips, then fill as needed with resin/glass beads (white) or Awl Grip fairing compound (pink). The same operations apply to the elevatore tips. Sand, fit, fill, rinse, repeat…

Here is a case of trying to level the HS tips, then fill as needed with resin/glass beads (white) or Awl Grip fairing compound (pink). The same operations apply to the elevatore tips. Sand, fit, fill, rinse, repeat…

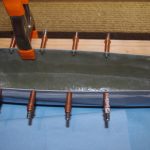

The left shows backing washers clecoed for superglue attachment to the elevator tips. These are not required, as these holes are supposed to be countersunk, then pop riveted onto the elevator. However, experience has shown the fiberglass gets very thin after the countersink operation, so this attempt should reinforce the connection.

The left shows backing washers clecoed for superglue attachment to the elevator tips. These are not required, as these holes are supposed to be countersunk, then pop riveted onto the elevator. However, experience has shown the fiberglass gets very thin after the countersink operation, so this attempt should reinforce the connection.

… and while waiting for the next round 0f build-up to cure, I started adding the nutplates to the horizontal stabilizer. Eventually these will fasten a custom fairing which sits between the horizontal and vertical stabilizers.