Work on the vertical stabilizer and rudder fairings was recently completed – at least for the time being and until final preparations for paint are underway.

My overall satisfaction level is good with the overall fit, gaps and blending of skins to fairings.

My overall satisfaction level is good with the overall fit, gaps and blending of skins to fairings.

The upper and lower elements are clecoed in position to check the final rudder angles, gap tolerance on the upper rudder swing and rudder/vs skin clearance. All within tolerance and acceptable for now.

The upper and lower elements are clecoed in position to check the final rudder angles, gap tolerance on the upper rudder swing and rudder/vs skin clearance. All within tolerance and acceptable for now.

The next fairings to be addressed are on the horizontal stabilizer. To properly fit these, Section 11 Tailcone Attach elements must first be completed. The elevators are fastened to the rod end bearings of the HS, then angles and clearances checked for free movement.

adfa

Here the HS cradles in the jig built many moons ago with the original construction. The elevators are in position to begin work on the fairing alignment.

Here the HS cradles in the jig built many moons ago with the original construction. The elevators are in position to begin work on the fairing alignment.

Close-ups of the gap between elevator tips and horizontal stabilizer, then the rod end bearding and the hinges.

Close-ups of the gap between elevator tips and horizontal stabilizer, then the rod end bearding and the hinges.

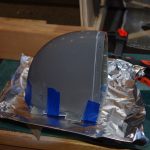

Initial fiberglass filling of the HS end caps after rough trimming to shape with the elevator tips. These are not straight – bending backwards at an 8degree angle. This is enough to prevent the fiberglass molding from being simple.

Initial fiberglass filling of the HS end caps after rough trimming to shape with the elevator tips. These are not straight – bending backwards at an 8degree angle. This is enough to prevent the fiberglass molding from being simple.