The cowl attachment points, pins and finalized baffling were performed throughout the last three month period as time permitted and was available between paint/prime sessions.

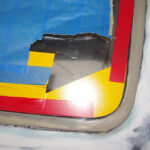

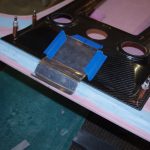

Many RV10 builders have reported the #5 cylinder chronically has the highest CHT temperatures – mainly due to the lack of airflow over the cylinder head. One of the solutions mentioned in the forums is apply the RV14 baffle mod to correct this situation. Here the mod is laid out and provisionally fit on the standard right-rear baffle.

Many RV10 builders have reported the #5 cylinder chronically has the highest CHT temperatures – mainly due to the lack of airflow over the cylinder head. One of the solutions mentioned in the forums is apply the RV14 baffle mod to correct this situation. Here the mod is laid out and provisionally fit on the standard right-rear baffle.

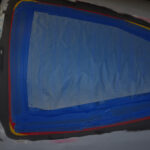

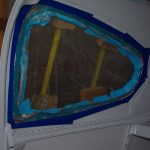

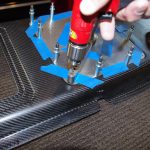

These photos show front and rear views of the installed RV14 mod. Note the carbon fiber motor mount covers from Aerosport Products.

These photos show front and rear views of the installed RV14 mod. Note the carbon fiber motor mount covers from Aerosport Products.

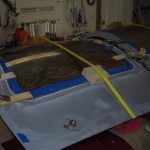

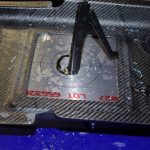

Another issue reported by many builders is the extreme heat generated by the heater muff during normal operations. One solution is throttle the intake air flowing to going to the heater access tubes. I added restricting plates to the front and rear heater inlets which can be removed by loosening only two screws.. The volume of air going through these openings can now be easily adjusted.

Another issue reported by many builders is the extreme heat generated by the heater muff during normal operations. One solution is throttle the intake air flowing to going to the heater access tubes. I added restricting plates to the front and rear heater inlets which can be removed by loosening only two screws.. The volume of air going through these openings can now be easily adjusted.

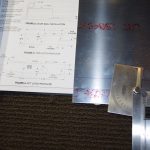

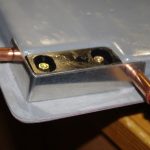

Attachment of the Aerosport low profile handles started with the base plate install (left). The handle with an enclosed return spring was then secured with a 1/8 x 3/4″ spring pin. Later the center locking cam wheels of the PlaneAround latching system were as secured with spring pins. (not shown)

Attachment of the Aerosport low profile handles started with the base plate install (left). The handle with an enclosed return spring was then secured with a 1/8 x 3/4″ spring pin. Later the center locking cam wheels of the PlaneAround latching system were as secured with spring pins. (not shown)

Here the edge tape from the door painting session was removed. The inner coverings were left attached in anticipation of the fuselage move on the highway from the shop to the airport. The final door configuration is shown on the right.

Here the edge tape from the door painting session was removed. The inner coverings were left attached in anticipation of the fuselage move on the highway from the shop to the airport. The final door configuration is shown on the right.

.

Adding Skybolt Camlocks to the lower cowl was a simple activity. In retrospect I would probably use that fastening system instead of piano hinges on all cowling parts. The cowl parts are MUCH easier to attach/remove with the Camlocks over inserting hinge pins in curved channels.

Adding Skybolt Camlocks to the lower cowl was a simple activity. In retrospect I would probably use that fastening system instead of piano hinges on all cowling parts. The cowl parts are MUCH easier to attach/remove with the Camlocks over inserting hinge pins in curved channels.

The Camlocks still needed depth adjustments on the cowl scoop before actual flight operations, but they were serviceable as-is for purposes of transporting the fuselage.

The Camlocks still needed depth adjustments on the cowl scoop before actual flight operations, but they were serviceable as-is for purposes of transporting the fuselage.

Here is a closeup of the door against the cabin center column. The next step was tape the roughed in door into position, get ready to install hinges.

Here is a closeup of the door against the cabin center column. The next step was tape the roughed in door into position, get ready to install hinges.