After preparing the latch pockets, now the latch pin guides. These are originally intended to secure the Van’s weatherstripping. I want to add them as a framework for some resin around the pin blocks. The idea here is fully enclose the pin blocks in order to provide a smooth, sealed surface for the McMaster seals. Yes – the pin blocks will be permanently encased in the door, but there are ways to install or remove the pins without dismounting the pin blocks. (more on that topic will appear in later posts)

First steps are layout the pin guides on a sheet of .040″ aluminum. The designated 6.8degree angle supposedly compensates for the angled door frames. A protractor is used to get the angle close (only has degree increments).

First steps are layout the pin guides on a sheet of .040″ aluminum. The designated 6.8degree angle supposedly compensates for the angled door frames. A protractor is used to get the angle close (only has degree increments).

Stiff construction paper prototypes were cut prior to making any metal parts. I wanted to check the effect of the angles on the corners. Close enough for some hand shaping to be effective.

Stiff construction paper prototypes were cut prior to making any metal parts. I wanted to check the effect of the angles on the corners. Close enough for some hand shaping to be effective.

The roughed out pin guides are then inserted in Tal’s sheet metal bender and formed per plan instructions.

The roughed out pin guides are then inserted in Tal’s sheet metal bender and formed per plan instructions.

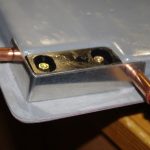

Here are the pin guides prior to fitting on the doors. Actual fitting required a bit of material removal. In retrospect I would first fit the pin guide hole from a slightly larger blank template, then shape down the attachment tabs to fit to the door geometry.

Here are the pin guides prior to fitting on the doors. Actual fitting required a bit of material removal. In retrospect I would first fit the pin guide hole from a slightly larger blank template, then shape down the attachment tabs to fit to the door geometry.

Here are the raw and final fits on the passenger door aft guide. Getting the pin hole aligned properly took time with hand filing. The final gaps are good.

Here are the raw and final fits on the passenger door aft guide. Getting the pin hole aligned properly took time with hand filing. The final gaps are good.

Here is a passenger door forward guide. Much easier since this is a straight piece. Now everything is ready for alodine/prime and covering the pin block with resin.

Here is a passenger door forward guide. Much easier since this is a straight piece. Now everything is ready for alodine/prime and covering the pin block with resin.