More sanding, fitting and filler on the fiberglass parts. Plus the addition of nut plates at various locations to complete some of the parts.

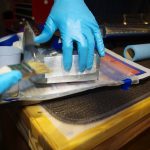

This photo shows the lower rudder fairing with #6 nut plates soft riveted into place. I made this fairing removable, as the AeroLED Suntail nav/strobe light wiring and electonics still needs to be added. A machined spacer from Cleaveland Tools provides a stable surface for fastening the Suntail afterwards.

This photo shows the lower rudder fairing with #6 nut plates soft riveted into place. I made this fairing removable, as the AeroLED Suntail nav/strobe light wiring and electonics still needs to be added. A machined spacer from Cleaveland Tools provides a stable surface for fastening the Suntail afterwards.

Final filler and smoothing on the bottom rudder skins. These parts hold the bottom fairing.

Final filler and smoothing on the bottom rudder skins. These parts hold the bottom fairing.

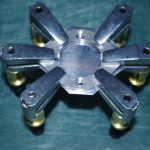

Nut plates for #6 screws are also install on the vertical stabilizer top. These will allow removal of the top to access the VOR bracket made earlier.

Nut plates for #6 screws are also install on the vertical stabilizer top. These will allow removal of the top to access the VOR bracket made earlier.

The bottom of the vertical stabilizer skins also takes #6 nut plates. These holes will later be used to fasten the fairing which bridges between the vertical and horizontal stabilizers.

The bottom of the vertical stabilizer skins also takes #6 nut plates. These holes will later be used to fasten the fairing which bridges between the vertical and horizontal stabilizers.