This week was about sanding and fitting the rudder top and bottom fairings.

This shows the top fairing pop-riveted into position on the rudder. The end cap with the lead counter-weight needed some additional material to match well with the VS top.

This shows the top fairing pop-riveted into position on the rudder. The end cap with the lead counter-weight needed some additional material to match well with the VS top.

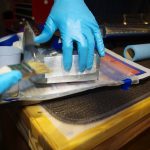

Plastic electrical tape is applied to keep the resin off unwanted parts. Then the end cap is sanded and cleaned for fiberglass layers. These are probably not necessary, but I wanted to ensure the overlapping metal parts are held rigidly in place (should help prevent cracking along the seam)

Plastic electrical tape is applied to keep the resin off unwanted parts. Then the end cap is sanded and cleaned for fiberglass layers. These are probably not necessary, but I wanted to ensure the overlapping metal parts are held rigidly in place (should help prevent cracking along the seam)

Multiple layers of fiberglass and resin are applied. Because the resin is quite fluid at the start, some droops down the lower face. This will later be sanded smooth and covered with Awl Grip D8200 for the final finish.

Multiple layers of fiberglass and resin are applied. Because the resin is quite fluid at the start, some droops down the lower face. This will later be sanded smooth and covered with Awl Grip D8200 for the final finish.

The basement shop was also enhanced with a new single stage, 12.8cfm air compressor made in USA by Quincy. Next steps are get the electrician to wire a dedicated circuit, then fire up for plane building usage.

The basement shop was also enhanced with a new single stage, 12.8cfm air compressor made in USA by Quincy. Next steps are get the electrician to wire a dedicated circuit, then fire up for plane building usage.