Finish configuration of wing root covers required installation of a few system components.

The rear spar bolt was an AN6-11, anchor nut and cotter pin. The wing root fairing supports are held primarily by LP4-3 pull rivets.

The rear spar bolt was an AN6-11, anchor nut and cotter pin. The wing root fairing supports are held primarily by LP4-3 pull rivets.

A custom fuel line, filter and shut-off valve from TSFlightline was installed. This configuration should allow the filter to be removed for annual inspection without the need to completely drain the tanks.

A custom fuel line, filter and shut-off valve from TSFlightline was installed. This configuration should allow the filter to be removed for annual inspection without the need to completely drain the tanks.

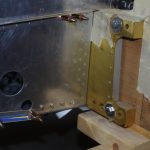

The massive and high precision bolts (NAS1309-58 and NAS1306-58) were tightened with the nylon insert (AN365-918 and AN365-624) lock nuts and regular/thin washers to expose sufficient bolt threads. The torques were 100 lb-ft and 20 lb-ft respectively

The massive and high precision bolts (NAS1309-58 and NAS1306-58) were tightened with the nylon insert (AN365-918 and AN365-624) lock nuts and regular/thin washers to expose sufficient bolt threads. The torques were 100 lb-ft and 20 lb-ft respectively

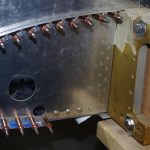

The Stewart-Warner IE-F-385C (right) fuel sender was attached with NAS180-2-0808 (8-32) hex head bolts and Permatex Aviation Forma-Gasket sealer compound.

The Stewart-Warner IE-F-385C (right) fuel sender was attached with NAS180-2-0808 (8-32) hex head bolts and Permatex Aviation Forma-Gasket sealer compound.

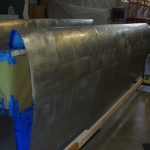

Fuel sumping valves were installed and fuel vent lines were fabricated from 1/4″ stainless tube.

Fuel sumping valves were installed and fuel vent lines were fabricated from 1/4″ stainless tube.

Lastly a Garmin GTP59 air temperature probe was installed near the first inspection port. This last run allowed the wire bundles to be consolidated and attached via CPC-24 connector to the fuselage.

Lastly a Garmin GTP59 air temperature probe was installed near the first inspection port. This last run allowed the wire bundles to be consolidated and attached via CPC-24 connector to the fuselage.