Bending metal for the wing root fairings and making brackets for the seats were the tasks for this week.

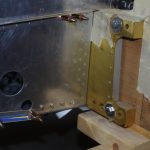

To achieve the correct bend of the fairing attach brackets, they must first be clecoed at one end. Flute pliers are used to align the pre-drilled locations in the fuselage mid-skins with the brackets.

To achieve the correct bend of the fairing attach brackets, they must first be clecoed at one end. Flute pliers are used to align the pre-drilled locations in the fuselage mid-skins with the brackets.

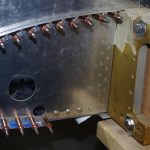

The fluting/bending process continues until all brackets align. The holes are then match drilled to final dimensions. These photos are show the forward brackets.

The fluting/bending process continues until all brackets align. The holes are then match drilled to final dimensions. These photos are show the forward brackets.

Here is the rear bracket. Another task prior to wing attachment is relieve the main spars where the bottom skins attach. Note the amount to be removed marked with a black Sharpie. The removal was by hand with Pferd files.

Here is the rear bracket. Another task prior to wing attachment is relieve the main spars where the bottom skins attach. Note the amount to be removed marked with a black Sharpie. The removal was by hand with Pferd files.

SEAT BRACKETS

The forward seats require additional brackets (not included in the quickbuild kit). The standard process for file, deburr, scotchbrite, brightener, alodine, prime, paint, and rivet was applied.