This week I finished squeezing all the spar rivets, which concluded the standard build portion of the horizontal stabilizer. My technical counselor suggest 5 drill-outs on the inner spar sections, so these have also been completed.

Squeezing the spar rivets is a one-man job, so these were completed alone.

Squeezing the spar rivets is a one-man job, so these were completed alone.

Eric did stop by for bucking the inner spar rivets and setting the final 25 inch/pound torque on the center hinge bracket bolts.

Eric did stop by for bucking the inner spar rivets and setting the final 25 inch/pound torque on the center hinge bracket bolts.

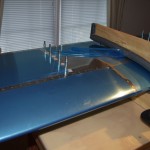

The final product is good, but not as clean as I would have liked. A few minor optical dents and dings, but should be safe otherwise.

The final product is good, but not as clean as I would have liked. A few minor optical dents and dings, but should be safe otherwise.

All the finished parts so far (rudder, VS, HS) are stored on the overhead shelf to avoid “shop rash” from being bumped during the processing of other parts. I used 18″ bubble wrap between the parts, and eventually covered all with thin plastic to keep out dust and dirt. The nice part is being in the bonus room, temperature controls and humidity are not a problem.

All the finished parts so far (rudder, VS, HS) are stored on the overhead shelf to avoid “shop rash” from being bumped during the processing of other parts. I used 18″ bubble wrap between the parts, and eventually covered all with thin plastic to keep out dust and dirt. The nice part is being in the bonus room, temperature controls and humidity are not a problem.