This week was all about riveting the horizontal stabilizer parts together. The whole job is not yet complete, but good progress was made on bucking the nose, spars and some inboard ribs. I had help from both Eric and Rich during the period.

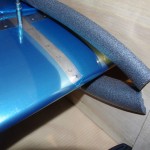

Oops. Notice the small, but still visible blemish near the most forward rivet. This came from the tungsten bucking bar pounding the reverse side of what we were processing. The bar as I held it was wide enough to span from one skin side to another. Drats. For later rivets I rearranged holding the bar parallel to the rib, not perpendicular to it as in this case. Hopefully this can be smoothed away with filler before painting. The only saving grace is this appears on the underside of the horizontal stabilizer. People will have to bend over and look from beneath to see it.

Oops. Notice the small, but still visible blemish near the most forward rivet. This came from the tungsten bucking bar pounding the reverse side of what we were processing. The bar as I held it was wide enough to span from one skin side to another. Drats. For later rivets I rearranged holding the bar parallel to the rib, not perpendicular to it as in this case. Hopefully this can be smoothed away with filler before painting. The only saving grace is this appears on the underside of the horizontal stabilizer. People will have to bend over and look from beneath to see it.

During the week and after doing the nose ribs, I prepped for riveting along the spars. AN426AD3-4 rivets are used for the outer section, AN426AD3-4.5 for the inner parts where the spar caps are located.

During the week and after doing the nose ribs, I prepped for riveting along the spars. AN426AD3-4 rivets are used for the outer section, AN426AD3-4.5 for the inner parts where the spar caps are located.

Eric comes over after work most nights for dinner. On this occasion I pressed him into service for a few hours doing the outer skin-to-forward spar rivets.

Eric comes over after work most nights for dinner. On this occasion I pressed him into service for a few hours doing the outer skin-to-forward spar rivets.

Here are the prep stages for the inner spar riveting.

Here are the prep stages for the inner spar riveting.

Rich came over on Saturday to help me complete the upper skin riveting in its entirety. The small cells between the stringers, inboard ribs and spar are quite tight for my big hands. It takes lots of repositioning of the bucking bar to see well into those cavities.

Rich came over on Saturday to help me complete the upper skin riveting in its entirety. The small cells between the stringers, inboard ribs and spar are quite tight for my big hands. It takes lots of repositioning of the bucking bar to see well into those cavities.

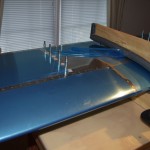

Here’s what it looks like on the outside as of Sunday morning. All the upper skin rivets are set (actually the bottom on this photo), the lower skins have been riveted to the forward spar. The inner rivets and placing the rear spar up for next week.

Here’s what it looks like on the outside as of Sunday morning. All the upper skin rivets are set (actually the bottom on this photo), the lower skins have been riveted to the forward spar. The inner rivets and placing the rear spar up for next week.

Upon inspection I found a number of scratch marks where the bucking bar had rubbed against the spar during rivet setting. This happened despite putting duck tape on the forward spar and the bucking bar for protection. My plan is to get a small Preval brand sprayer to prime over this spots before closing off with the rear spar.

Upon inspection I found a number of scratch marks where the bucking bar had rubbed against the spar during rivet setting. This happened despite putting duck tape on the forward spar and the bucking bar for protection. My plan is to get a small Preval brand sprayer to prime over this spots before closing off with the rear spar.

Another trick employed was fitting a felt chair leg cushion to the end of the bucking bar. When used in conjunction with duck tape against the spar, this seemed to eliminate any scratching. Another prime example of live, innovate and learn.

Another trick employed was fitting a felt chair leg cushion to the end of the bucking bar. When used in conjunction with duck tape against the spar, this seemed to eliminate any scratching. Another prime example of live, innovate and learn.