Bonding the overhead console and painting the canopy interior were completed over the holidays.

Lord 7545A/E two part epoxy adhesive is combined through a static mixer tube with 21 cross-linking elements, then spread generously along the flanged edge of the Aerosport Products carbon-fiber overhead console

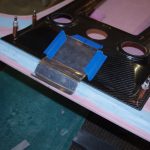

Clecoes, weights, spring clamps and sandbags are used to hold the console in place while the adhesive drys. Some folks have performed this operation with the canopy already on the plane, but doing it with the canopy overturned allows gravity to be my friend.

Clecoes, weights, spring clamps and sandbags are used to hold the console in place while the adhesive drys. Some folks have performed this operation with the canopy already on the plane, but doing it with the canopy overturned allows gravity to be my friend.

After 24 hours of cure time, the Lord adhesive has finished bonding the surfaces together. Next is blending the overhead flange into the canopy interior surface. Multiple layers of Super-Fil are applied and sanded until the transition between parts is invisible. Layers of Poly Fiber Smooth Prime are rollered onto all the fiberglass surfaces.

After 24 hours of cure time, the Lord adhesive has finished bonding the surfaces together. Next is blending the overhead flange into the canopy interior surface. Multiple layers of Super-Fil are applied and sanded until the transition between parts is invisible. Layers of Poly Fiber Smooth Prime are rollered onto all the fiberglass surfaces.

The Smooth Prime is sanded in final preparation of priming/painting the canopy interior. The standard PPG DP48LP Primer and DCC Concept paint will be applied as with all the other interior components.

The Smooth Prime is sanded in final preparation of priming/painting the canopy interior. The standard PPG DP48LP Primer and DCC Concept paint will be applied as with all the other interior components.

Staged, degreased, and ready for treatment in Tal’s paint booth.

Staged, degreased, and ready for treatment in Tal’s paint booth.

And here are the outcomes after two coats of primer and one coat of paint. I think these turned out very well.

And here are the outcomes after two coats of primer and one coat of paint. I think these turned out very well.