After months of working on shop/logistics and dealing with some health problems, I finally got back to working on real plane parts.

Lining up the stiffeners, bulkheads and skins can be an interesting proposition by yourself. Fortunately Rita and Peter were available to help on the most demanding sections.

Lining up the stiffeners, bulkheads and skins can be an interesting proposition by yourself. Fortunately Rita and Peter were available to help on the most demanding sections.

The plans call for hanging the pieces from sawhorses, but I found placing the pan on the workbenches covered by carpet with clecoes from the inside to be a more comfortable arrangement. Here clecoes are being applied after #40 match drilling the stiffeners and bulkheads.

The plans call for hanging the pieces from sawhorses, but I found placing the pan on the workbenches covered by carpet with clecoes from the inside to be a more comfortable arrangement. Here clecoes are being applied after #40 match drilling the stiffeners and bulkheads.

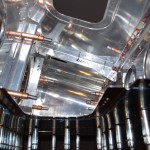

A few shot from inside looking backwards from where the rear seat would be. It is amazing how each of these fragile parts when fastened together properly can be so strong. With the stiffeners in place, the whole assembly is quite rigid.

A few shot from inside looking backwards from where the rear seat would be. It is amazing how each of these fragile parts when fastened together properly can be so strong. With the stiffeners in place, the whole assembly is quite rigid.

The left picture shows where the rudder stop bracket is attached inside the final tailcone section. The right shows the final bulkhead (where the tie-down bracket is on the lower inside).

The left picture shows where the rudder stop bracket is attached inside the final tailcone section. The right shows the final bulkhead (where the tie-down bracket is on the lower inside).