After a week on business travel, I returned to finish fitting the skins, stiffeners, longerons, aft deck, and doublers.

Here drilling the aft top skin to the stiffeners.

Here drilling the aft top skin to the stiffeners.

Fluting the frames is required to get a smooth curve on the skins.

Fluting the frames is required to get a smooth curve on the skins.

Walking the forward top skin to the frames. This time I started at the top and moved downward.

Walking the forward top skin to the frames. This time I started at the top and moved downward.

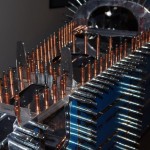

Rita says it looks like a porcupine. I think it looks great.

Rita says it looks like a porcupine. I think it looks great.

Next day I drilled and clecoed all the aft deck parts.

Next day I drilled and clecoed all the aft deck parts.

The horizontal stabilizer attachment points are reinforced with 3-4 extra pieces of fabricated aluminum. This photo from above shows the alignments along the center line.

The horizontal stabilizer attachment points are reinforced with 3-4 extra pieces of fabricated aluminum. This photo from above shows the alignments along the center line.

Close-up of the clamped, then final attachment brackets.

Close-up of the clamped, then final attachment brackets.

Here is the aft deck fully drilled and clecoed.

Here is the aft deck fully drilled and clecoed.