Now that the airplane has been moved to the airport and wings attached, final painting and installations can proceed.

Interior panels from Aerosport Products were primed with PPG DP48LF white primer. Later the panels were painted PPG Concept Boeing Grey.

Interior panels from Aerosport Products were primed with PPG DP48LF white primer. Later the panels were painted PPG Concept Boeing Grey.

The foam backed, fabric material was glued into place on the Aerosport headliner with contact cement by professional auto specialists. (Don’t ask why I did not do this myself). The backing fiberglass was then fitted with Velcro strips and attached to corresponding strips on the canopy.

The foam backed, fabric material was glued into place on the Aerosport headliner with contact cement by professional auto specialists. (Don’t ask why I did not do this myself). The backing fiberglass was then fitted with Velcro strips and attached to corresponding strips on the canopy.

More views of the overhead console and installed headliner..

More views of the overhead console and installed headliner..

The left photo shows fitting the map pockets on the forward interior panels prior to prime/paint. The right photo shows the baggage bulkhead after painting.

The left photo shows fitting the map pockets on the forward interior panels prior to prime/paint. The right photo shows the baggage bulkhead after painting.

A Blue Seas power outlet was fitted onto the baggage bulkhead. A 10A fuse and toggle switch for directing trickle charge power to either PRI or SEC battery were installed with switch guards. This outlet is not intended for ever jump starting the aircraft. The required EXPERIMENTAL decal was installed on the upper bulkhead cover.

A Blue Seas power outlet was fitted onto the baggage bulkhead. A 10A fuse and toggle switch for directing trickle charge power to either PRI or SEC battery were installed with switch guards. This outlet is not intended for ever jump starting the aircraft. The required EXPERIMENTAL decal was installed on the upper bulkhead cover.

The lower bulkhead cover was fitted with UHDP wear blocks for the rear shoulder harness cables. The right picture shows a rear interior panel with the air vent cover installed.

The lower bulkhead cover was fitted with UHDP wear blocks for the rear shoulder harness cables. The right picture shows a rear interior panel with the air vent cover installed.

Preparation of the Aerosport dashboard cover included installation of covers for the panel fan outlets and trimming the edges for fit. After trim, I used my fledgling sewing skills to dress the edges against fraying.

Preparation of the Aerosport dashboard cover included installation of covers for the panel fan outlets and trimming the edges for fit. After trim, I used my fledgling sewing skills to dress the edges against fraying.

The center console and control stick wiring was completed and tested. Labelling of the jack ports was with a Brother P-touch. I would have preferred a laser etched alternative, but maybe than can be a future project.

The center console and control stick wiring was completed and tested. Labelling of the jack ports was with a Brother P-touch. I would have preferred a laser etched alternative, but maybe than can be a future project.

The dashboard cover was secured with 1″ and 2″ Velcro strips.

The dashboard cover was secured with 1″ and 2″ Velcro strips.

Final dashboard cover, center console and control sticks installed…

Final dashboard cover, center console and control sticks installed…

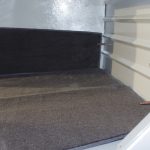

Front and rear footwell carpet…

Front and rear footwell carpet…