This week a stainless strike plate for the oil door camlock latches was fabricated, as well as a backing plate for the Cleaveland Tool hidden hinge.

These photos show the application of West Marine resin / colloidal silica mixture to the upper cowl in preparation for riveting the hinges and oil door in-place.

These photos show the application of West Marine resin / colloidal silica mixture to the upper cowl in preparation for riveting the hinges and oil door in-place.

Backing plates for the oil door hinges and the latches were also fabricated from .032″ aluminum pieces. The plates were bonded to the fiberglass substrate with resin adhesive, followed by cleces in place during the curing process. The whole door was then sprayed with heat resistant aluminum paint. Finally all the parts were fastened together with AN426A (soft) rivets.

Backing plates for the oil door hinges and the latches were also fabricated from .032″ aluminum pieces. The plates were bonded to the fiberglass substrate with resin adhesive, followed by cleces in place during the curing process. The whole door was then sprayed with heat resistant aluminum paint. Finally all the parts were fastened together with AN426A (soft) rivets.

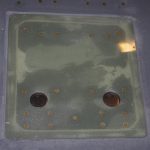

Here the oil door is dry fit in cowl opening.

Here the oil door is dry fit in cowl opening.

SuperFil was applied to even the profile differences between the cowl and the door itself. After this dries, all parts will be sanded smooth and prepared for further process of cowl fitting.

SuperFil was applied to even the profile differences between the cowl and the door itself. After this dries, all parts will be sanded smooth and prepared for further process of cowl fitting.

Here is the interim result ready for prime/paint. Note the push buttons are slightly recessed. Depending on the final paint job, I may address making these more flush with the surface.

Here is the interim result ready for prime/paint. Note the push buttons are slightly recessed. Depending on the final paint job, I may address making these more flush with the surface.