Eric and I disassembled the rudder today. First up was deburr everything and dimple the skins. After this I went ahead with measuring and drilling the attachment points for the bonding straps on both the vertical stabilizer and rudder spars. The process was the same described in earlier posts for the static wicks.

The swivel handle with a #40 countersink bit attached goes much faster and just as cleanly as twirling with my fingers. It is also much easier on hands and forearms. We dimpled both rudder skins after this step.

The swivel handle with a #40 countersink bit attached goes much faster and just as cleanly as twirling with my fingers. It is also much easier on hands and forearms. We dimpled both rudder skins after this step.

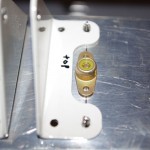

This is a mock-up of how the nut plate for the bonding strap will look on the backside of the rudder.

This is a mock-up of how the nut plate for the bonding strap will look on the backside of the rudder.

I wanted the bonding strap in the middle hinge location of the vertical stabilizer, close to the upper bracket of the pair – and horizontally aligned with its opposite partner on the rudder. This mock-up shows how close to the bracket I was able to place the nut plate. The horizontal alignment also turned out near perfect.

I wanted the bonding strap in the middle hinge location of the vertical stabilizer, close to the upper bracket of the pair – and horizontally aligned with its opposite partner on the rudder. This mock-up shows how close to the bracket I was able to place the nut plate. The horizontal alignment also turned out near perfect.

This is how the final configuration should look. The nut plate jig works great! After so much time doing research and thinking about how to make these modifications, I am very pleased with the outcome.

This is how the final configuration should look. The nut plate jig works great! After so much time doing research and thinking about how to make these modifications, I am very pleased with the outcome.