In addition to the start of deburring all the horizontal stabilizer parts, I have also begun marking those pieces to be trimmed or created from angle aluminum.

Two of the spar ribs require parts of the tabs to be removed. Here the particular portions are noted with a Sharpie.

Two of the spar ribs require parts of the tabs to be removed. Here the particular portions are noted with a Sharpie.

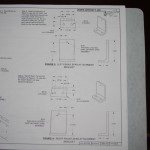

Manufacturing two attachment brackets from 2″ x 2.5″ angle aluminum is going to be a real challenge. I do not have precision equipment to get the holes drilled to the tolerances laid out in the plans. I will probably ask my technical counselor on some much needed advice before moving forward.

Manufacturing two attachment brackets from 2″ x 2.5″ angle aluminum is going to be a real challenge. I do not have precision equipment to get the holes drilled to the tolerances laid out in the plans. I will probably ask my technical counselor on some much needed advice before moving forward.

Here is my markup of the angle aluminum used for the attachment brackets.

Here is my markup of the angle aluminum used for the attachment brackets.

Laying a 5/8inch sheet of MDF on the bench top provides a seamless surface to the DRDT-2. This picture shows the MDF will support the skin exactly level with the male die for the dimpling operation.

Laying a 5/8inch sheet of MDF on the bench top provides a seamless surface to the DRDT-2. This picture shows the MDF will support the skin exactly level with the male die for the dimpling operation.