Further fitting the VS top and rudder bottom fairing were the activity for this week.

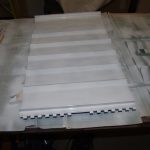

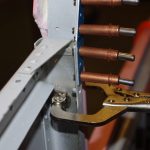

The VS top fairing did not fit properly in the metal opening. Throughout this build I have found all the fiberglass parts to only be approximations, much work on proper alignment and sizing has been needed. Here the rear profile is being sanded to shape and the back panel straightened to match the rudder top fairing.

The VS top fairing did not fit properly in the metal opening. Throughout this build I have found all the fiberglass parts to only be approximations, much work on proper alignment and sizing has been needed. Here the rear profile is being sanded to shape and the back panel straightened to match the rudder top fairing.

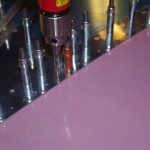

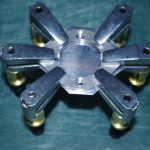

The AeroLED Suntail NAV/strobe will be attached to the lower rudder fairing via a machined aluminum spacer purchased from Cleaveland Tool. The fiberglass from the fairing at this point is fairly thin, so fabricating a backing plate for the six pull rivets was chosen. This photo shows interim progress.

The AeroLED Suntail NAV/strobe will be attached to the lower rudder fairing via a machined aluminum spacer purchased from Cleaveland Tool. The fiberglass from the fairing at this point is fairly thin, so fabricating a backing plate for the six pull rivets was chosen. This photo shows interim progress.