After two weeks in Germany on vacation and visiting relatives, I got back to a few miscellaneous activities previously started a while back. The first was riveting the spar reinforcement brackets into place using the excellent tandem piston, alligator rivet squeezers Rich had obtained in an estate sale. I had refurbished the squeezer itself months back (see past postings), but did not have the appropriately sized squeezer dies for -3 or -4 rivets. I finally located a source in Florida called Delta International and ordered the right size for the job. They arrived on Thursday and on Saturday riveting began.

I first used the AHARS platform as an off-plane test of the squeezer. It takes a bit of adjusting with shims to get the pressure/offset between the heads correctly for a good squeeze depth. Plus the stationary arm of the alligator jaws must be the one with the AN470 die. Otherwise, the shop side of the rivet will be bent or smushed down incorrectly. With a bit of practice on the platform parts, I was able to get consistently excellent results. So glad I continued the advice never to do something for the first time directly on the plane.

Here is the squeezing operation in progress. The alligator jaws are perfect for going around the bulkhead angles from the side. Not sure it would even be possible with a standard C-yoke configuration give the tight space laterally along the side walls.

Here is the squeezing operation in progress. The alligator jaws are perfect for going around the bulkhead angles from the side. Not sure it would even be possible with a standard C-yoke configuration give the tight space laterally along the side walls.

Excellent. The results speak for themselves. I love putting old tools to good use.

Excellent. The results speak for themselves. I love putting old tools to good use.

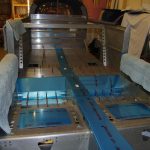

I am now getting close to priming the insides of the plane. Beforehand though, a last set of tunnel and seat covers needs to be prepped. Here the vinyl covered parts are staged in their appropriate locations. What follows are the standard fit, drill, deburr, and prime steps.

I am now getting close to priming the insides of the plane. Beforehand though, a last set of tunnel and seat covers needs to be prepped. Here the vinyl covered parts are staged in their appropriate locations. What follows are the standard fit, drill, deburr, and prime steps.