This was a power weekend – alodine and priming my first set of plane parts with expert assistance from Rich.

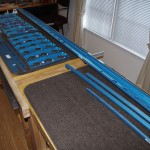

Here we are finishing the air handling system for the shed.

Here we are finishing the air handling system for the shed.

Getting staged for mixing brightener – dilute phosphoric acid with brand name PPG DX533 (one part to three parts distilled water).

Getting staged for mixing brightener – dilute phosphoric acid with brand name PPG DX533 (one part to three parts distilled water).

The actual mixing process occurred in the shed to keep any fumes or spills out of the house.

The actual mixing process occurred in the shed to keep any fumes or spills out of the house.

Here Rich and I are posing in front of the treated parts, first dunked in the brightener solution and rinsed with water. The drying racks just hold the pieces before the alodine process, no real need to have them bone dry at this point.

Here Rich and I are posing in front of the treated parts, first dunked in the brightener solution and rinsed with water. The drying racks just hold the pieces before the alodine process, no real need to have them bone dry at this point.

One of the VS spars goes into the alodine solution in the dunk tank. The first pieces in the fresh solution for 2 minutes turned very dark, so the immersion time was adjusted to get a more golden color. Everything was hung overnight with a space heater on for complete drying. This is necessary before the priming steps.

One of the VS spars goes into the alodine solution in the dunk tank. The first pieces in the fresh solution for 2 minutes turned very dark, so the immersion time was adjusted to get a more golden color. Everything was hung overnight with a space heater on for complete drying. This is necessary before the priming steps.

Suited up and shaking the PPG DF40LF grey-green primer. I only got a quart, which turned out to be way more than needed for this batch of parts.

Suited up and shaking the PPG DF40LF grey-green primer. I only got a quart, which turned out to be way more than needed for this batch of parts.

Using a graduated measuring cup marked for 2:1 primer to catalyst.

Using a graduated measuring cup marked for 2:1 primer to catalyst.

Rich took this picture through the shed window showing primer actually being applied to some parts.

Rich took this picture through the shed window showing primer actually being applied to some parts.