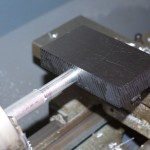

Cutting pass through holes for 5/8″ conduit under the rear seat panels is no easy chore. With the quickbuild kit, the ribs are already riveted into position about 4″ apart. Getting a large Unibit into proper alignement is impossible. My method was use a right-angle pneumatic drill attachment to start a small pilot hole, then enlarge with a hand file to a size big enough to accommodate a knock-out set.

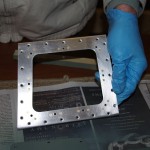

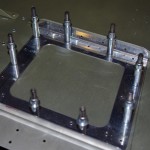

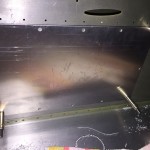

The set needs a 1/2′ pilot hole, then the first punch-out occurs by tightened the 11/16″ driving screw. On the right is the rough opening for 3 conduit runs.

The set needs a 1/2′ pilot hole, then the first punch-out occurs by tightened the 11/16″ driving screw. On the right is the rough opening for 3 conduit runs.

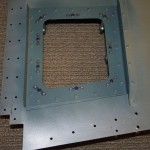

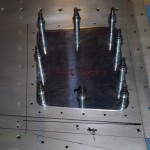

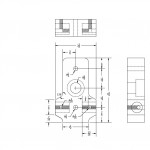

This shows the full circle first cut, then subsequent half-moon chunks taken out progressive to make the elongated opening for the conduits.

This shows the full circle first cut, then subsequent half-moon chunks taken out progressive to make the elongated opening for the conduits.

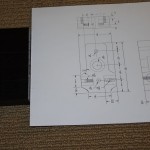

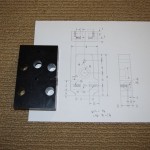

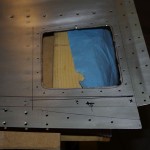

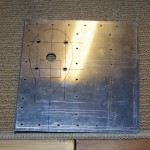

On the left side I made the backing plate first, then used is as a template to serve as a guide.

On the left side I made the backing plate first, then used is as a template to serve as a guide.

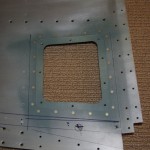

The second opening turned out much cleaner than the first. Of course this will not be visible to anyone after the seat panel is pop riveted closed.

The second opening turned out much cleaner than the first. Of course this will not be visible to anyone after the seat panel is pop riveted closed.

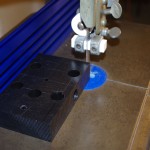

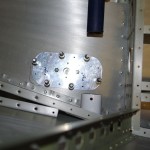

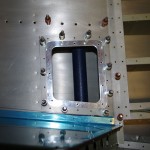

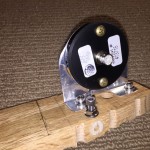

The pop rivet has a swivel head, but still there was barely enough room to operate. Slight flexing of both ribs was required to reach the bottom holes.

The pop rivet has a swivel head, but still there was barely enough room to operate. Slight flexing of both ribs was required to reach the bottom holes.

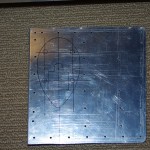

Final holes under the baggage floor have nylon grommets or conduit attachment brackets.

Final holes under the baggage floor have nylon grommets or conduit attachment brackets.